ALUMINUM & ZINC CASTING MADE AFFORDABLE, ACCURATE, REPEATABLE & COSMETIC

Alpha Foundry has a long history of innovation, exceptional quality, and trusted customer service. Our business is positioned to help customers at any level of their project, from initial start-up and accepting responsibility for a current project, to keeping your castings moving forward and filling in as an additional supplier. We are big enough to handle most needs, but small enough to narrow in and focus on your specific needs.

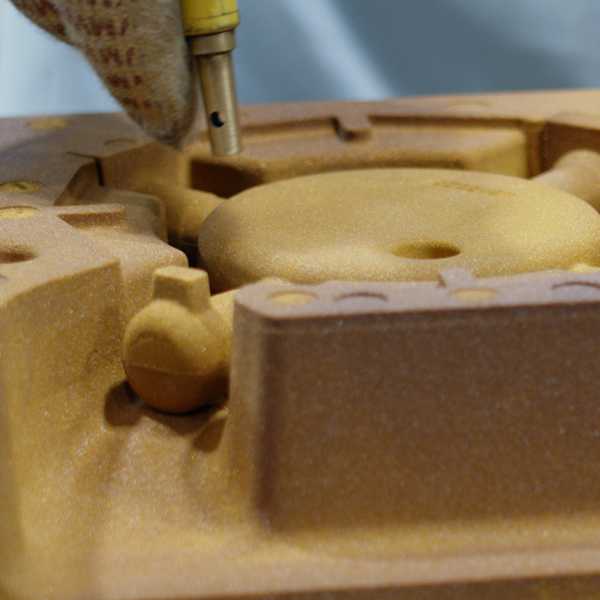

Our hybrid shell molding process – the “Alpha Process”- delivers impressive results that are not obtainable with conventional sand-casting technology. We also offer our innovative 3-D Core Production, which can help reduce your labor cost on core cleaning. Plus, our in-house Machining Services are available to deliver at any level, from start to a finished product.

CASTINGS

Our unique hybrid shell molding process produces castings with exceptional finish and precision.

![Alpha_Foundry_08[13] Alpha_Foundry_08[13]](https://www.alphafoundry.com/wp-content/uploads/2023/07/Alpha_Foundry_0813-600x600.png)

3D PRINTING

We also offer the latest in 3-D printed core production technology and machining services.

THE ALPHA PROCESS

Our process fills a void among different casting processes with the Shell Molding Process.

THE STORY

The original business was founded in 1920 as the Barron & Richter Pattern Company in St. Louis, MO. Since then, 3rd and 4th generation Barron’s Emerson and Son Ryan have invested in new processes and innovations that set them apart from traditional foundries.