Capabilities

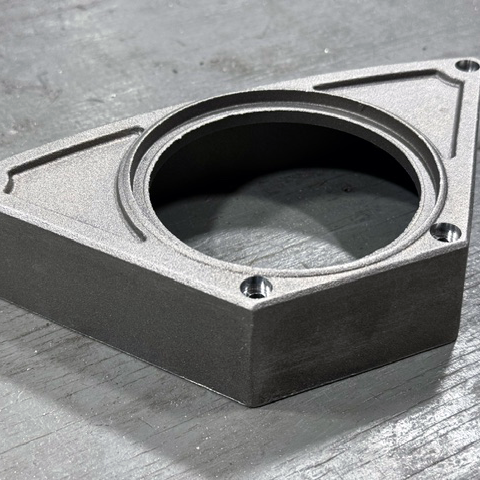

ADVANCED TECHNOLOGY IN MOLD & CORE PRODUCTION

Alpha Foundry now provides designers and engineers the ability to move quickly forward in your pursuit for prototype, one-off, small batch, and production level mold and core production. Alpha Foundry’s in-house ExOne™ S-Max® 3D Sand printer advances mold and core production with precision, speed, and design integrity. Our advanced technology exceeds in producing highly intricate designs, undercuts, and internal passages without the issues of traditional tooling constraints.

EXPERIENCE

Team Alpha has extensive experience in 3D sand printing, with thousands of cores produced and ensuring high-quality results for our customers.

EFFICIENCY

The ExOne™ 3D sand printing process is super-efficient, with most projects taking no more than a few hours to complete.

PRECISION PROTOCOLS

Our new ExOne™ 3D Sand Printer is the most advanced equipment available in the industry. With this model, you can expect precision and exactness all around.

TRUE FLEXIBILITY

We can accommodate your designs simply by inputing your specifications into our formulation guide, and from here provide you with an early estimate (cost and production time).

Alpha Foundrymen are casting pros.

We work with aluminum, zinc, and iron. Cast iron is stronger and harder than steel, thanks to its compressive strength and carbon-alloy composition. Alpha Foundry melts iron to over 3000º degrees and pours it into casts. We make thousands of castings for the electrical products industry.

- Casting Alloys: 356 Aluminum, ZA12 Zinc, Grey and Ductile Iron

- Casting Weight: Up to 20 pounds 356 aluminum and 40 pounds ZA-12 for production Alpha Process Castings-3D Sand Prototype castings up to 150 lbs cast iron

- Machining: Tooling Design/Production, Workholding, Drilling, Boring, Tapping, Thread milling, CNC Turning, Finishing, etc.

- Value-Added Services Available: Heat Treatment, Painting, Casting Impregnation, Anodizing, etc.

- Casting Dimensions: Up to 6” across parting line and 18” x 18” parallel to parting line for production Alpha Process Castings; 3D Sand Prototype Castings up to 24

With the S-Max® we have increased capacity, enhanced production, and offer our customers more value.

Faster, more efficient shell sand castings. Translation: premium castings without a premium price.

Our unique process yields solutions to many casting challenges, no matter the industry.